Shrink film heat tunnels are essential equipment for businesses that require packaging products efficiently and effectively. Whether you run a manufacturing plant, a food processing facility, or a retail operation, maintaining your shrink film heat tunnel can ensure optimal performance, reduce downtime, and extend the life of your equipment. This guide will provide valuable tips for maintaining your shrink film heat tunnel and maximizing its lifespan, ensuring your investment pays off for years to come.

Understanding the Importance of Maintenance

Before diving into specific maintenance tips, it’s essential to understand why regular upkeep is crucial for your shrink film heat tunnel. Like any machinery, consistent use can lead to wear and tear. Over time, components may degrade, which can affect efficiency and lead to costly repairs or replacements. By prioritizing maintenance, you can:

- Increase Efficiency: Regular upkeep ensures that your machine operates at peak performance, leading to faster packaging times and less waste.

- Reduce Downtime: Preventative maintenance can help you identify issues before they become significant problems, minimizing unexpected downtime.

- Extend Equipment Lifespan: Taking care of your equipment will ultimately lead to a longer lifespan and a better return on investment.

- Improve Safety: Regular inspections can help identify potential hazards, ensuring a safer working environment for your employees.

Maintenance Tips for Your Shrink Film Heat Tunnel

1. Regular Cleaning

Keeping your heat tunnel clean is one of the most critical aspects of maintenance. Dust, debris, and residue from shrink films can accumulate over time, impacting the machine’s performance.

- Daily Cleaning: Wipe down the exterior surfaces of the heat tunnel at the end of each day. Use a soft cloth and a mild cleaning solution to remove any dust or residue.

- Weekly Cleaning: Inspect and clean the conveyor belts and heating elements weekly. Remove any build-up that could impede performance. If possible, use a vacuum to clean inside the tunnel carefully.

- Monthly Deep Cleaning: Schedule a thorough cleaning of the entire machine once a month. Disassemble parts that are easy to remove, such as fans and filters, and clean them according to the manufacturer’s instructions.

2. Regular Inspections

Conducting routine inspections helps identify potential problems before they escalate. Create a checklist to guide your inspections.

- Check for Wear and Tear: Look for signs of wear on belts, rollers, and heating elements. If any parts appear worn, replace them promptly.

- Examine the Conveyor System: Check the alignment of the conveyor system. Misalignment can lead to uneven shrink wrapping and increase the risk of jams.

3. Proper Temperature Settings

Maintaining the correct temperature is vital for effective shrink wrapping and overall equipment performance. Operating the machine at the right temperature can also prevent unnecessary wear on the heating elements.

- Follow Manufacturer Guidelines: Always adhere to the temperature settings recommended by the manufacturer. Incorrect temperatures can lead to insufficient shrinkage or damage to products.

- Regularly Calibrate: Periodically check and calibrate the temperature settings to ensure they are accurate. An inconsistent temperature can lead to product quality issues.

4. Lubrication

Like any mechanical system, the moving parts of your shrink film heat tunnel require proper lubrication to function smoothly. Regularly lubricating these parts will reduce friction, wear, and heat generation.

- Identify Lubrication Points: Consult the manufacturer’s manual to identify all lubrication points on the machine.

- Use Appropriate Lubricants: Always use the recommended lubricant types. Using the wrong lubricant can lead to damage or ineffective operation.

- Create a Lubrication Schedule: Develop a routine lubrication schedule, whether it’s weekly, bi-weekly, or monthly, depending on the usage of your heat tunnel.

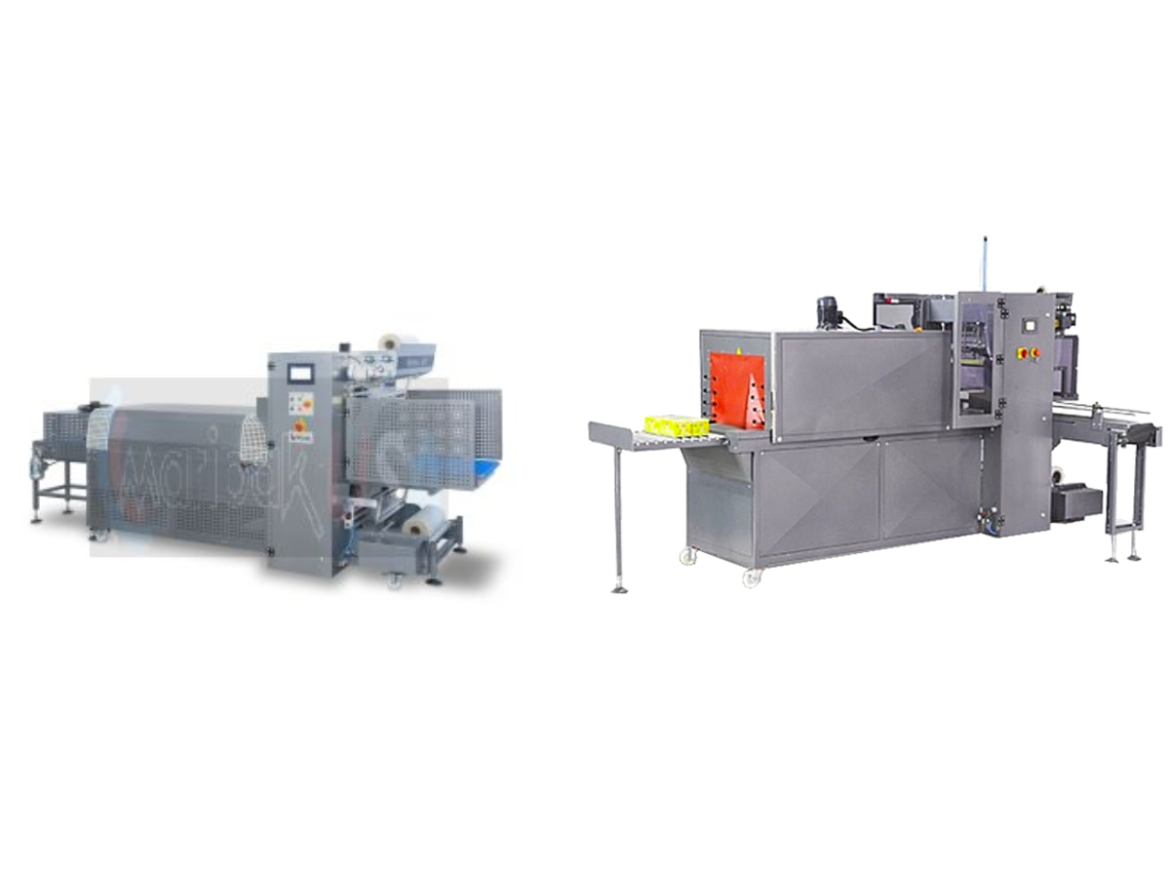

You can easily get the shrink film heat tunnels and shrink wrap machines for sale. But make sure you get it from a credible seller.

Conclusion

Maintaining your shrink film heat tunnel is essential for ensuring its efficiency, extending its lifespan, and reducing downtime. By implementing these maintenance tips—regular cleaning, inspections, proper temperature settings, lubrication, staff training, using quality materials, and following manufacturer recommendations—you can optimize your equipment’s performance and safeguard your investment.